In today’s fast-paced world where anyone with an idea can become an entrepreneur, some business concepts tend to be more popular than others. In fact, few budding business owners put stock into more “traditional” concepts like warehousing. Little do they know, these industries are solid money-makers that can provide value quickly. If you’re interested in starting up a warehousing business of your own, there are a few things to keep in mind before you pass “Go.”

Construction matters greatly

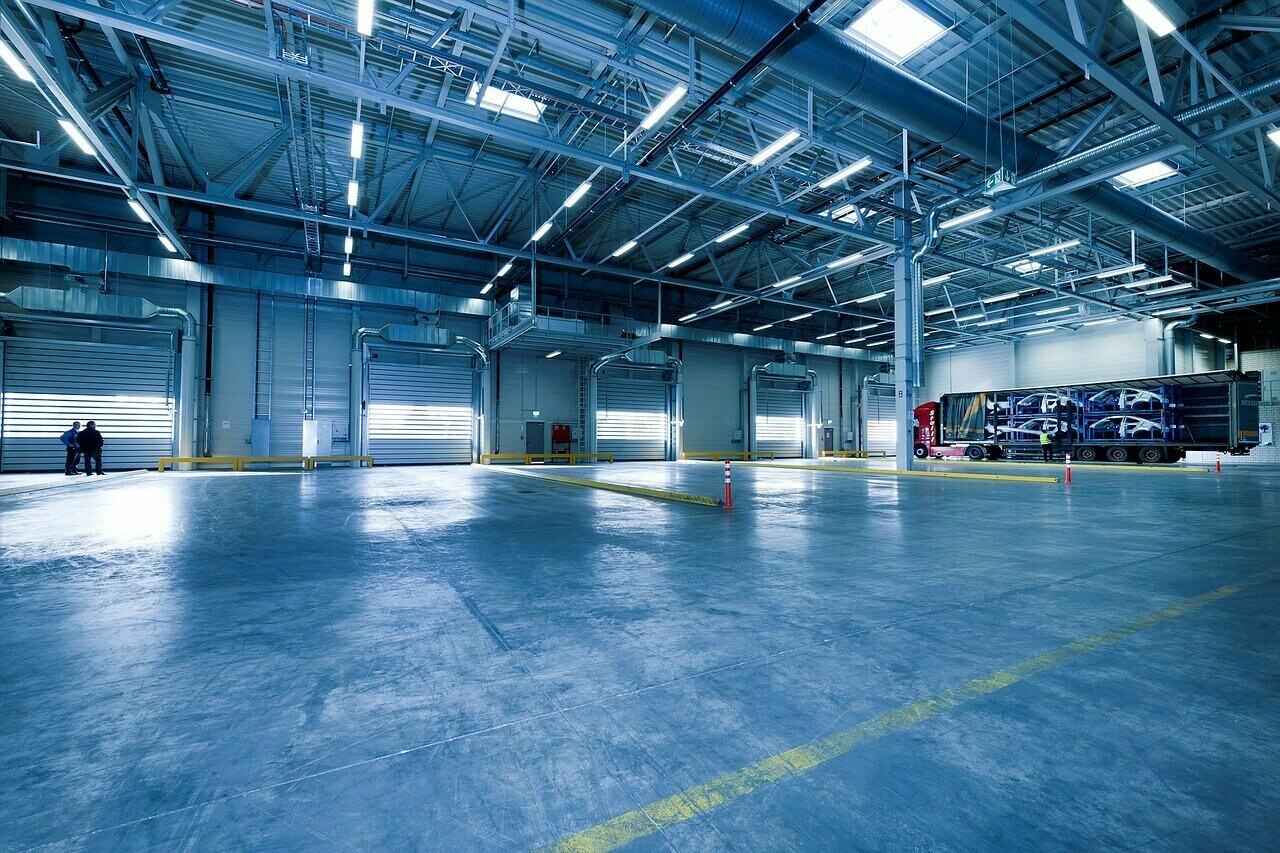

The key tenant of warehousing is, of course, the storage, organization, and distribution of goods. As such, it’s important for you to make sure that any structure you either build, lease, or purchase is up to par. Outdated structures might not offer enough in the way of protection from the elements. If you’re buying an older warehouse, some of its specifications might not even be up to modern regulations and standards, such as having commercial fire rated doors installed throughout the structure. It’s important to read the fine print and pay attention to the details whether you’re constructing your own warehouse or going with a preexisting space.

Other materials to keep in mind are the roofing as well as your internal layout. Make sure that you’re investing only in the sturdiest shelving options because one unfortunate collapse could lose you massive amounts of money and even sour business relationships. Once you’ve gotten these foundational pieces in place, you can start to think about work gear and equipment like forklifts and hand trucks. You’re also going to want to start thinking about some of the logistical and administrative aspects of your warehousing business, too.

Logistics and distribution

If you’re going to be running your own distribution network instead of relying on an existing one, logistics are going to take center stage. If you don’t have a head for numbers and contracts, this is where you’ll want to start thinking about sourcing some outside help. Hiring a logistics professional takes the stress of managing the shipping and receiving processes off of your shoulders. While shipping and receiving are key components of managing a distribution network, a logistics expert can also help with the fundamentals of your business, namely, the actual warehousing parts.

On top of receiving client products and tracking their positioning, a logistics specialist can determine where they should be stored and manage some of the organizational tasks throughout the warehouse. While there are several templates for a standard warehouse layout, you can still go through the trial and error process to determine which storage options work best for your operation. There’s no one-size-fits-all solution to the logistics of warehousing so it’s important to do some experimenting.

Find some customers

This is where having a solid, convincing value proposition comes in handy. Many potential customers could have existing warehousing and distribution contacts. “Why should they choose you?” is a question you need to be able to answer quickly and concisely. Do you offer better rates? Is your distribution method faster and more reliable? Find what sets you apart from the competition and hone in on it. If your message resonates with customers, you’re setting yourself up for success.

Warehousing isn’t for everyone, but for the right entrepreneur, it can be an incredibly fruitful business venture that pays out solid dividends to hard workers. Make sure you’re covering all your bases before you take on customers. There’s nothing more frustrating than coming across a knowledge gap in the middle of a contract. While it’s impossible to know everything without prior experience, some research and foresight can prevent common warehousing missteps and help you achieve your business goals more smoothly.